Narrow Gauge Shop takes special orders for layout baseboards (*not available at the moment).

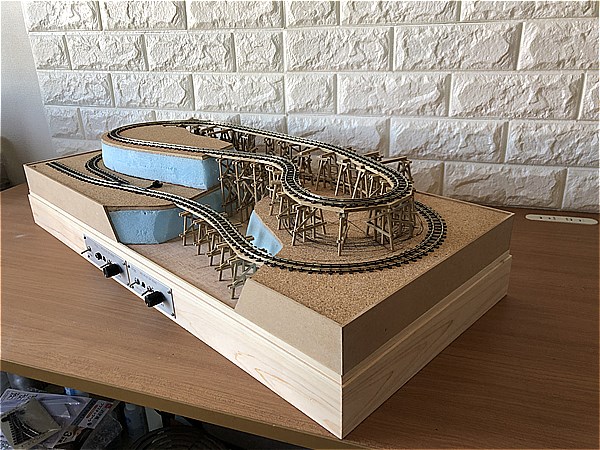

In this article we show you one of the custom made layout baseboards we made last year.

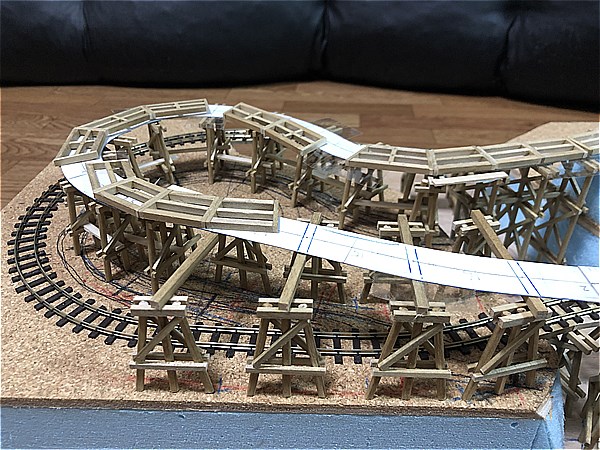

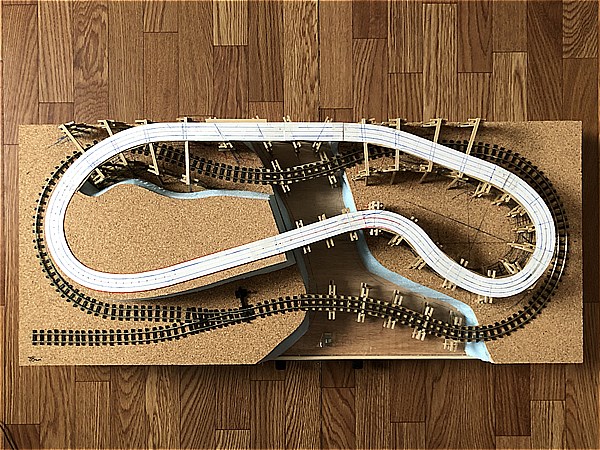

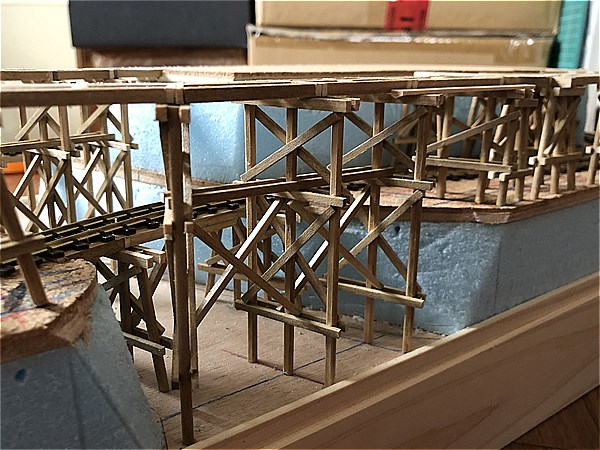

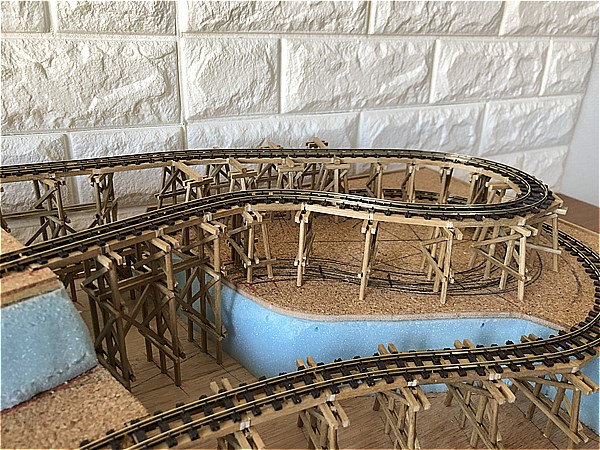

The diorama has now been added to the base and has evolved into a wonderful work of art. You can follow his work on Twitter (@schmalspurmodel).

・…━… 目次 …━…・‥

Customer's preferred specification

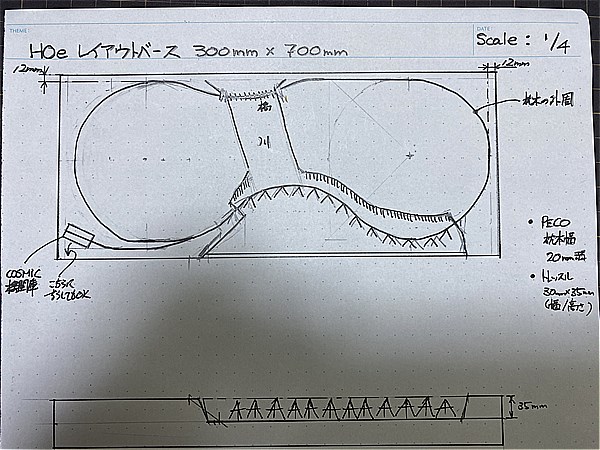

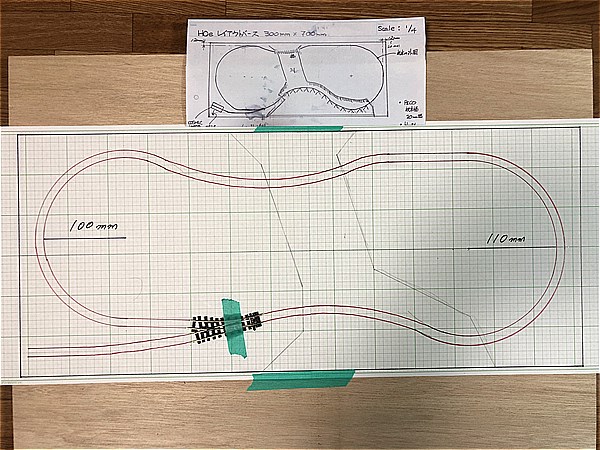

The first step is to find out what the customer wants. We ask him to send us his preferred size, scale, gauge and a rough layout plan.

One of the most important aspects of a special order is to find out everything the customer wants. This can be very difficult.

The following are the approximate specifications that the customer wants...

- Concept:Logging Railway

- Size:700mm x 300mm

- Scale/Gauge:HOe (9mm)

- Radius:Large radius where possible

- Tracks:PECO HOe Flexible track code80 (SL-400)

- Timber Trestle:Basswood

- Turnout:PECO HOe ST-405

- Manual Turnout Control:Caboose Industries #5218S N/HO scale

- Power Unit (AC-DC)

Logging layout planning

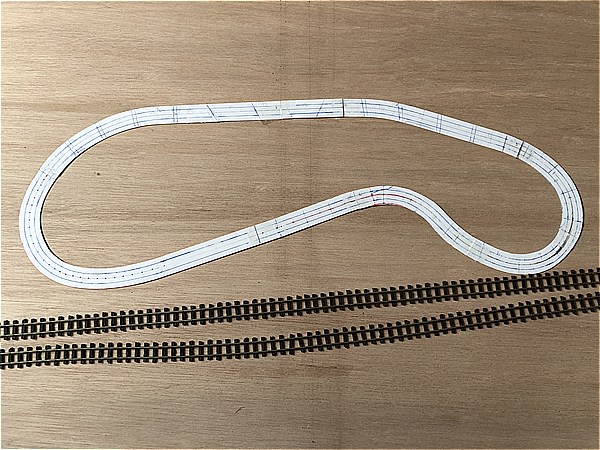

Based on the customer's layout plan, we draft a full-size drawing. He checks it, and if it is consistent with his image, we start work.

The second important aspect of a special order is to communicate frequently with the customer.

The minimum radius of the track layout was decided to be 100-110 mm, using PECO turnout ST-405.

Additional request

(Left) Narrow Gauge Shop

After we started production, the customer made an additional request.

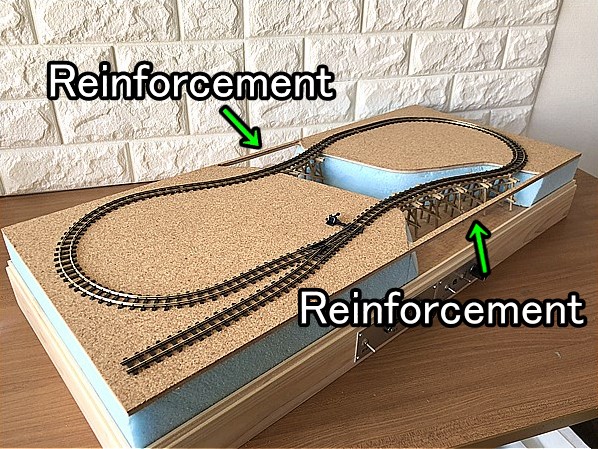

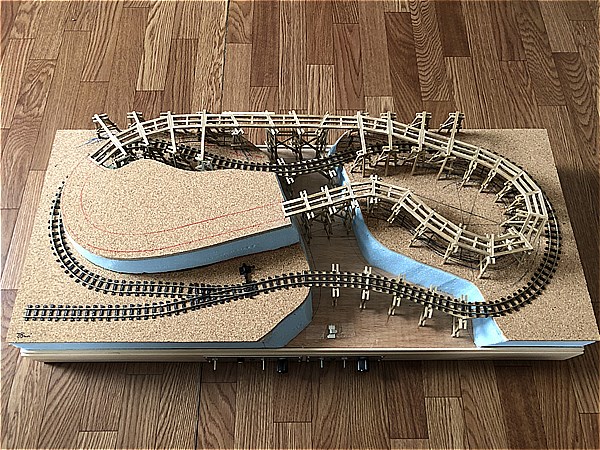

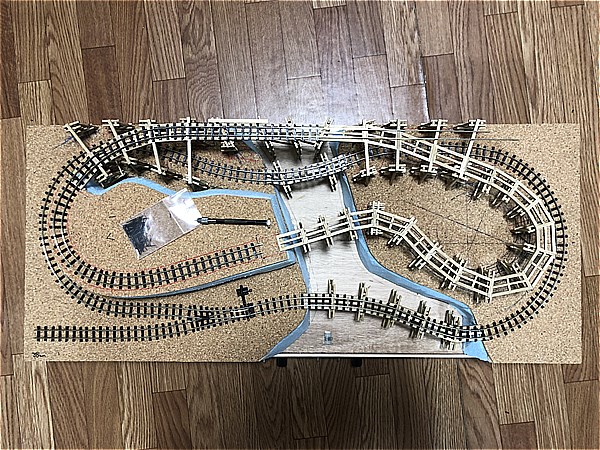

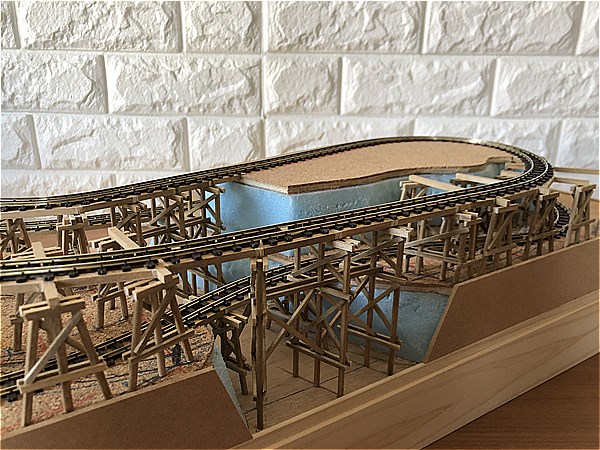

He also wanted us to build a two-level layout with another trestle. The production was fun and challenging, but the difficulty level was greatly increased.

We decided to complete the lower level first and then build the trestles to lay the upper level of track.

The third important aspect of a special order is that we do everything we can to fulfil the customer's wishes.

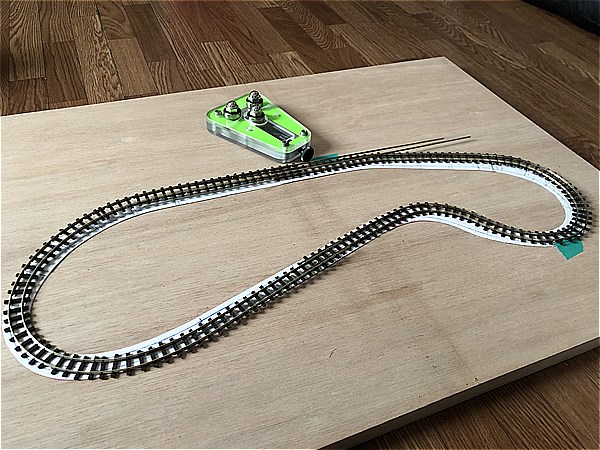

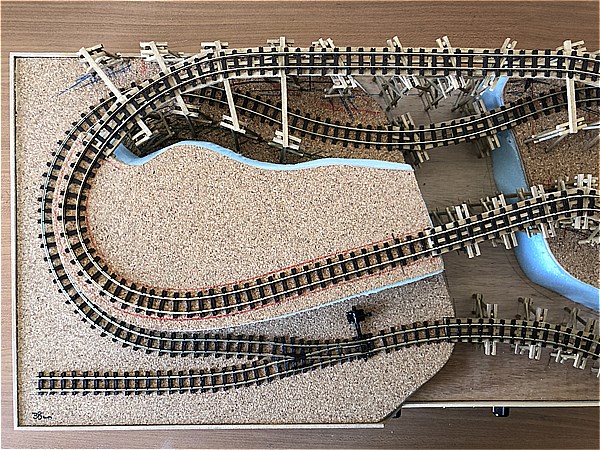

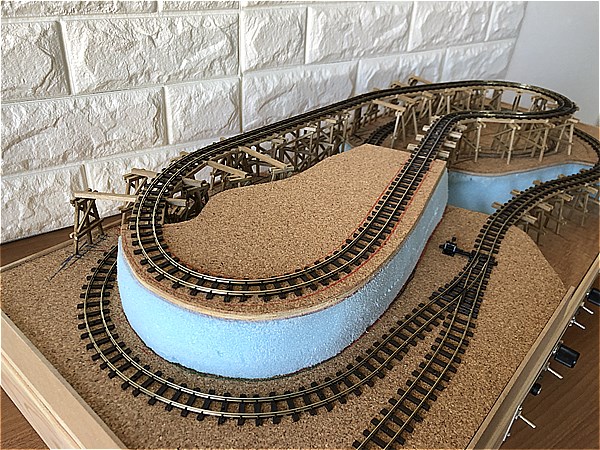

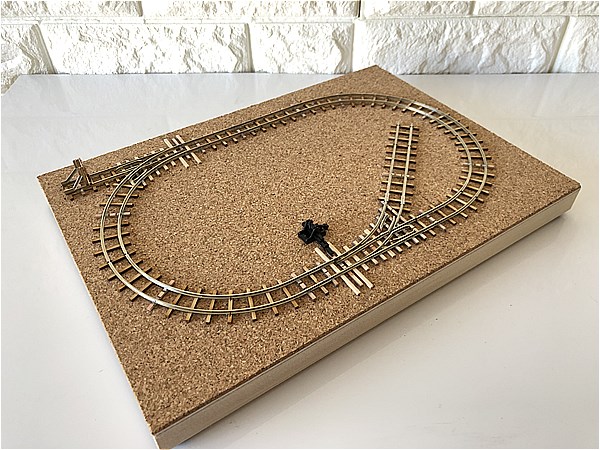

Completion of the lower level

- Base Frame:Japanese cypress

- Styrofoam:40mm

- Timber Trestle:Basswood

- Power Units:Lower Level(AC-DC)/Upper Level(12V dry cell battery powered)

We temporarily gave the layout baseboard to the customer so that he could plan the upper section. A few days later, he sent us a video of his test run.

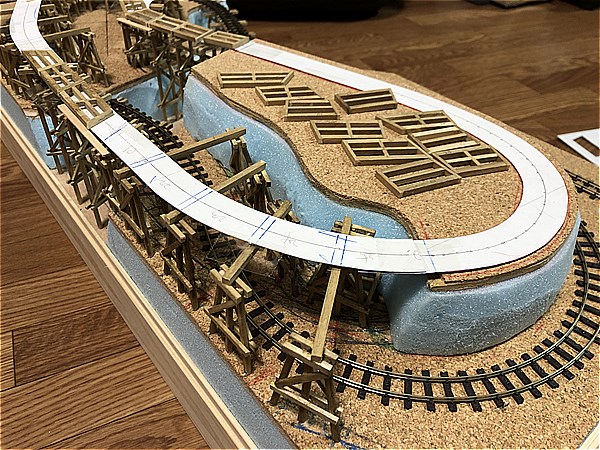

Then we start building the upper level

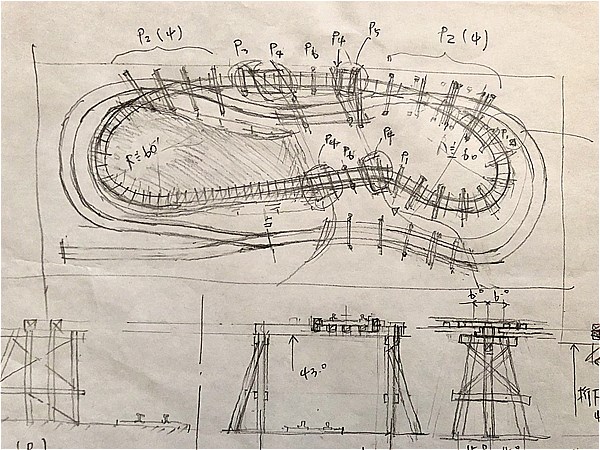

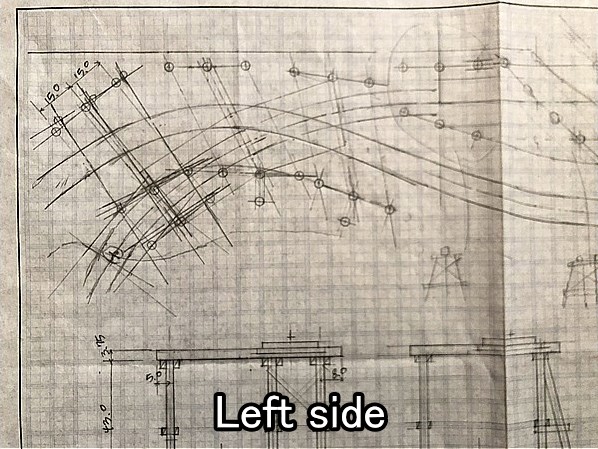

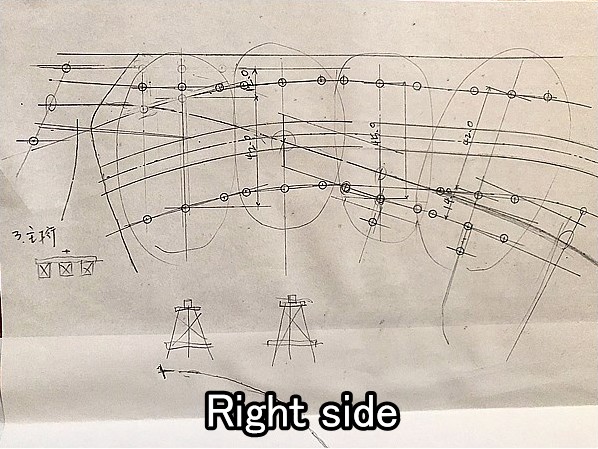

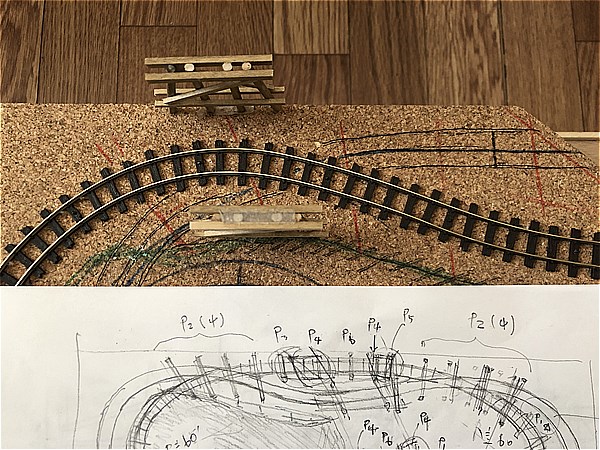

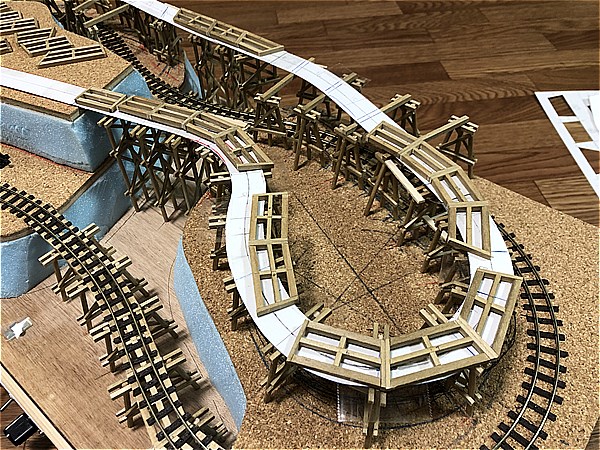

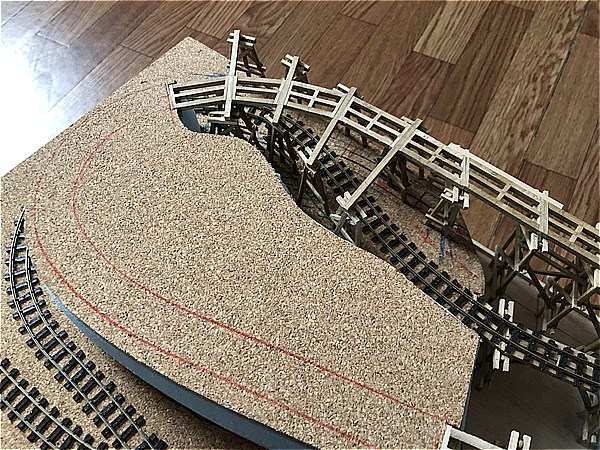

First, the customer drew up a rough layout plan. I then drew up detailed plans based on it. The drawing is very important.

The points we have to pay attention to are..

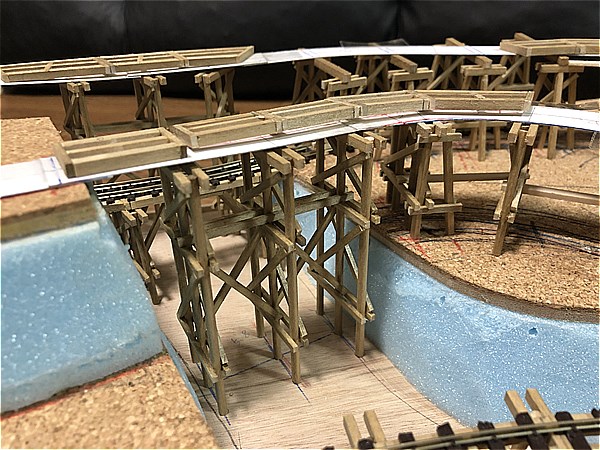

- The trestle across the river at the back

- The point where the lower and upper levels intersect

There is not enough space, so we are worried about the possibility of installing the trestles.

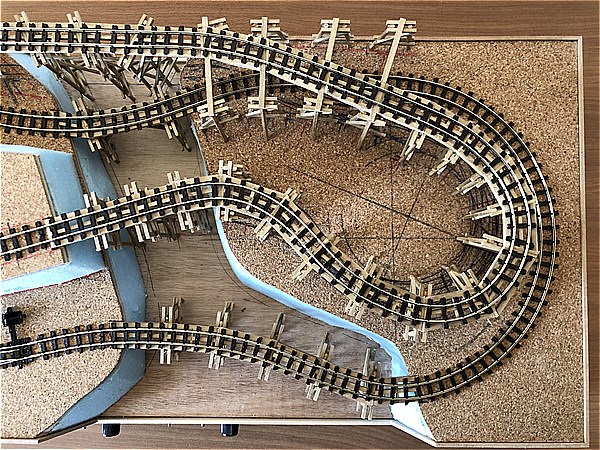

The track radius of the upper level is decided to be 55-60mm.

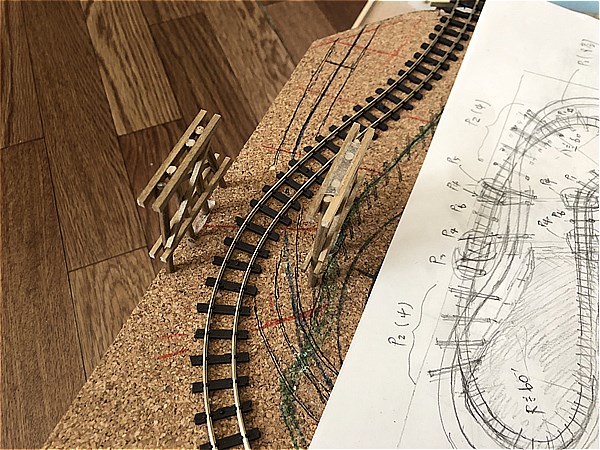

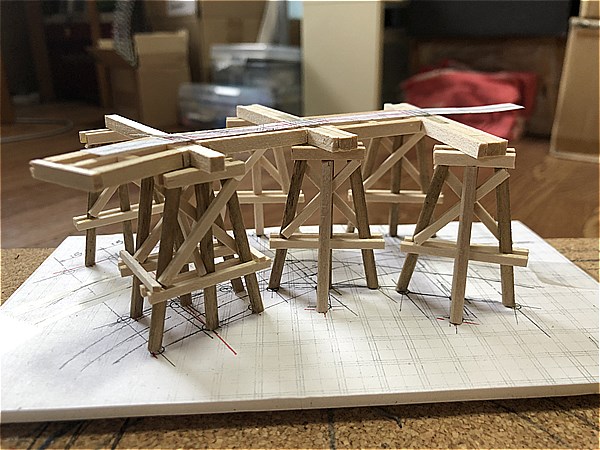

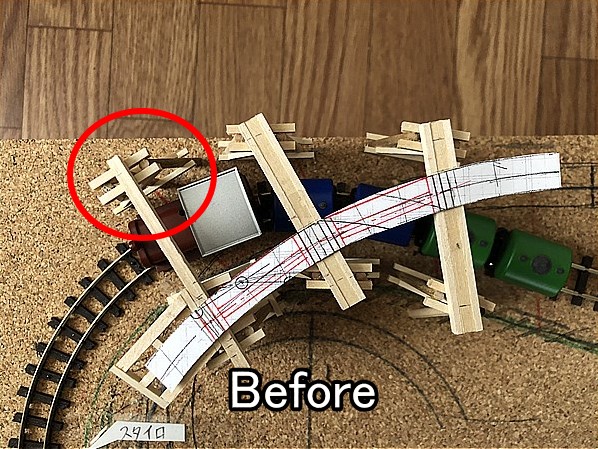

Make trestles and test them in kind

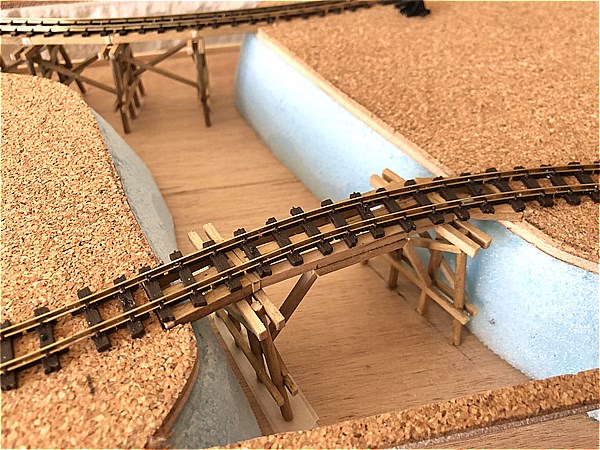

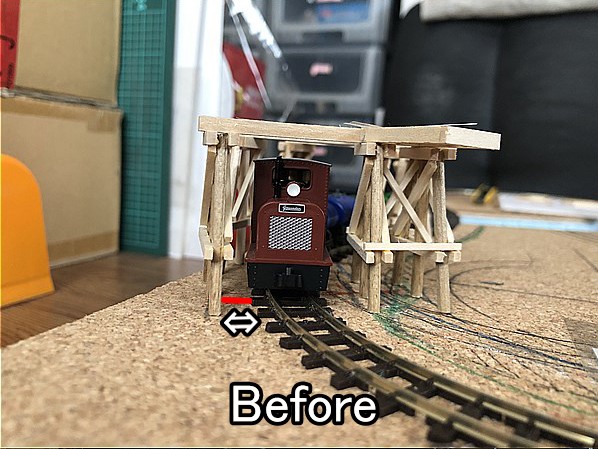

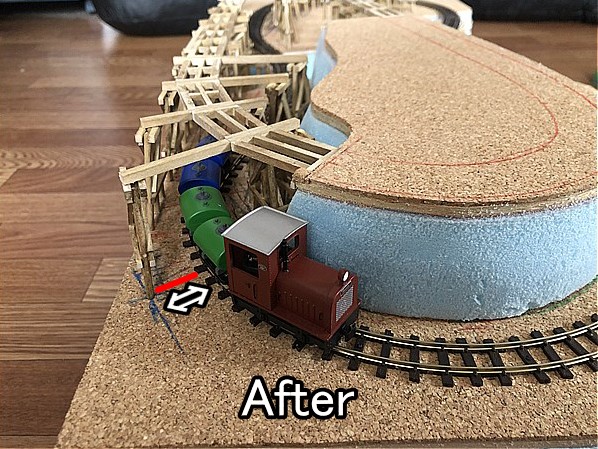

It's a bit of a tight squeeze, but I think I've got it.

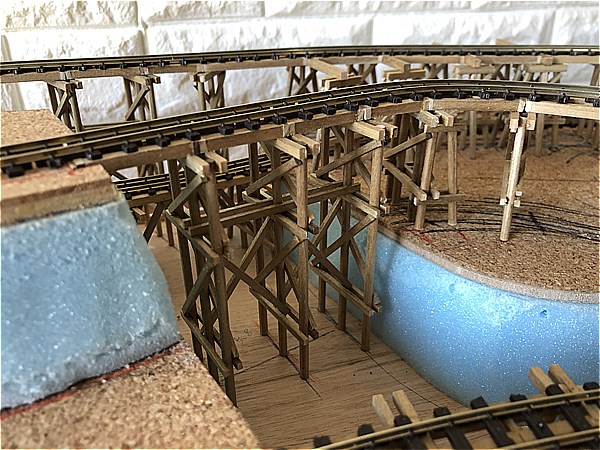

Especially on the left side, where the track under the trestle is curved, we have to be careful not to buffer the car against the trestle.

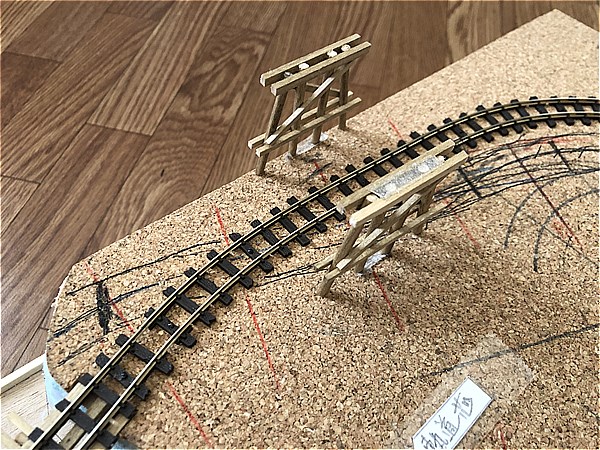

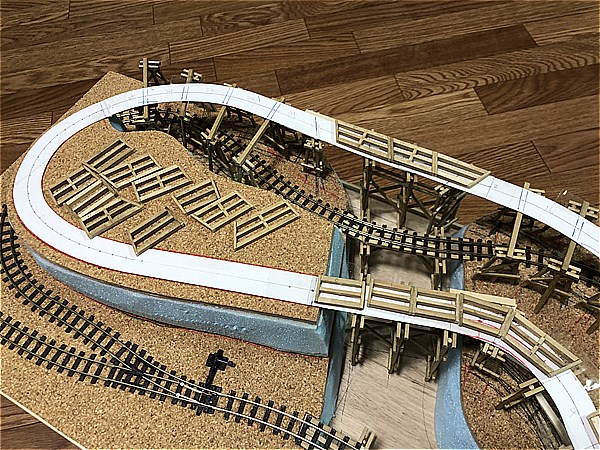

Assembling the trestles and test running

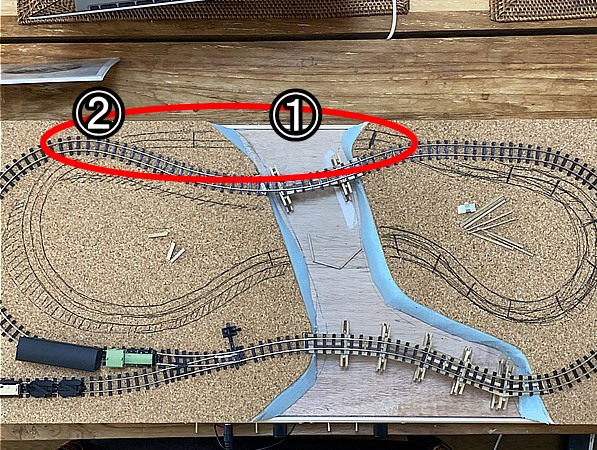

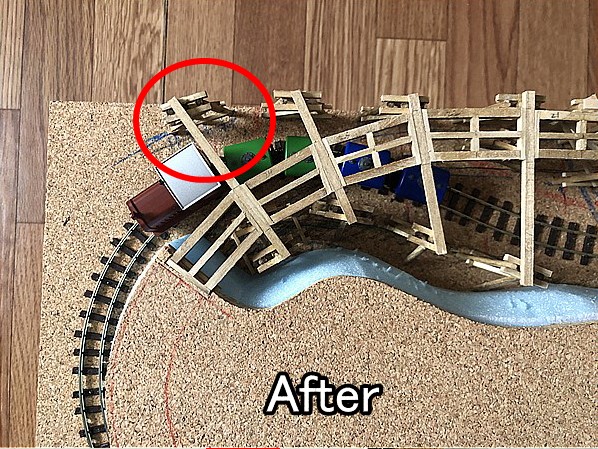

Particular attention has to be paid to the area shown in the three images above.

Some vehicles will need to be adjusted, but we confirmed that they will pass safely.

Determining the position of the track and bridge girder

The trestles are added and the terrain is aligned with the bridge girders using Styrofoam.

The position of the bridge girders is determined by adjusting them to the pattern of the track layout.

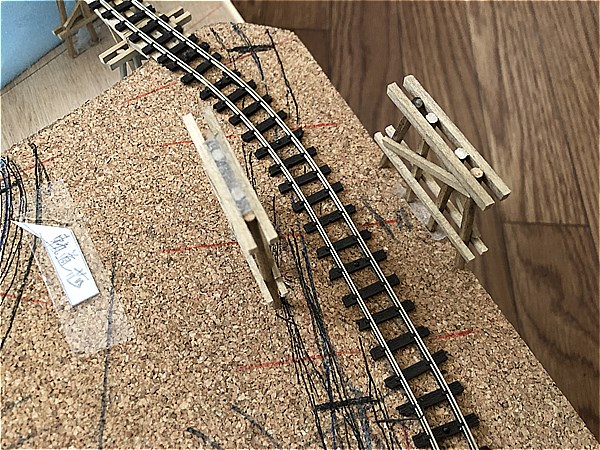

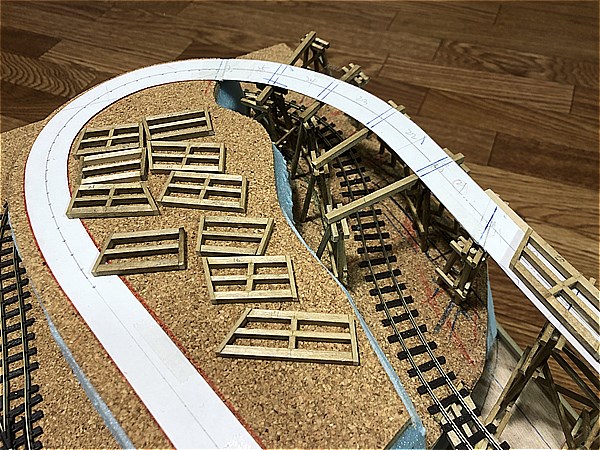

Adjustment of the trestles (left-hand crossing)

There was very little space on either side of the trestles, which was a concern, but by shifting the position of the trestles outwards, a small amount of room was gained.

Now that the track and bridge girders are in place, it is time to lay the PECO flextrack.

Laying flextracks

The radius of the track on the upper level is 55-60 mm, which is a sharp curve, so it is necessary to use a rail-bender to bend the track more firmly than on the lower level.

The ideally, as shown in the picture, the track should retain its approximate shape without being fixed to the base.

The tracks is carefully fixed with Track Fixing Pins.

Even if the Track Fixing Pins come loose, the track will not collapse as the track is bent tightly.

Custom made HOe Logging Layout Baseboard is completed

Successfully completed. The customer was very pleased with the powerful timber trestles.

The most important aspect of a special order is the customer's satisfaction.

This is a video sent to us by the customer later.

I was relieved to see that the longer coaches were able to run in the areas I was worried about.

Contact us

Please feel free to let us know what you would like us to sell!!

Narrow Gauge Shop

Satoru Mimura

1-15-27,Negishi,Machida,

Tokyo,JAPAN 194-0038

E-mail narrow_gauge_shop@ae.auone-net.jp

https://www.youtube.com/c/narrowgaugeshop

https://www.pinterest.jp/narrowgaugeshop/

We're very active on YouTube and Pinterest, so we'd love it if you'd subscribe to our channel (follow us) and hit the good button.

-

How to make HOe Micro Layout Baseboard with Self-made Turnout by Narrow Gauge Shop